10 Butcher Tools You Need to Master Meat Cutting

Equipping a butcher shop with key cutting tools like meat saws, butcher knives, and meat cleavers ensures precision, safety, and efficiency in meat processing. Additionally, investing in essential grinding and processing equipment, like meat grinders, sausage stuffers, and meat tumblers, enhances product variety and quality. Safety gear, hygiene practices, refrigeration solutions, and weighing devices are crucial for maintaining a safe, clean, and efficient butcher shop operation.

Diving into the world of butchery requires not just skill but also the right tools to ensure safety, efficiency, and quality in every cut. From the precision of a Chinese cleaver to the protective assurance of cut-resistant gloves, equipping yourself with the essentials can transform your meat processing from daunting to masterful.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Key Cutting Tools Every Butcher Needs

Navigating the world of butchery requires skill, patience, and the right set of tools. To ensure every cut is clean, precise, and efficient, there are a few key instruments every butcher should have on their bench.

Meat Saws for Precision Cutting

To handle the toughest jobs with ease, meat saws are indispensable. These powerful tools cut through bones and thick cuts of meat, making them a staple for processing large sections. Designed for durability and efficiency, meat saws come with hardened stainless steel blades and motors built for continuous use.

The precision they offer ensures minimal waste, optimizing every slice and maintaining the quality your customers expect. Always look for saws with ergonomic designs to ensure comfort and safety during use, keeping your butchery running smoothly.

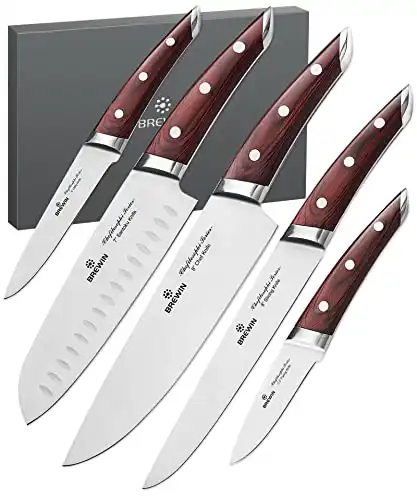

The Importance of Quality Butcher Knives

No butcher’s toolkit is complete without a set of high-quality knives. These knives must be sharp, durable, and comfortable to use, providing the control needed for intricate cutting tasks. From trimming fat to slicing through delicate tissues, a good butcher knife handles it all with precision.

Investing in a variety of shapes and sizes, including boning knives, carving knives, and fillet knives, allows for versatility in cutting techniques. Remember, the quality of your cuts can set you apart from the competition, so choose your knives wisely.

Using a Meat Cleaver for Tough Cuts

For the tougher tasks that require a bit more force, a meat cleaver steps up to the plate. This hefty tool is designed to hack through bones, cartilage, and thick meat cuts with less effort and more control. With its large, flat blade, a meat cleaver also doubles as a useful tool for crushing garlic or tenderizing meat. Selecting a meat cleaver with a comfortable grip and balanced weight distribution will make these challenging cuts feel effortless, enhancing the efficiency and safety of your butchery operations.

By arming yourself with these essential cutting tools, you’ll ensure that your butchery not only operates efficiently but also produces the highest quality cuts. Precision, durability, and safety are key, so invest in tools that won’t let you down.

Grinding and Processing Equipment

After discussing the essential cutting tools for precision and safety in butchery, let’s dive into the equipment that takes meat processing to the next level: the grinding and processing machines. These devices not only streamline operations but also expand the variety of meat products a butcher can offer.

The Role of Meat Grinders in a Butcher Shop

Think of meat grinders as the backbone of any meat processing operation. They’re designed for efficiency and versatility, allowing you to handle large quantities of meat with ease. Equipped with powerful motors, durable blades, and various grinding plates, meat grinders transform chunks of meat into ground or minced form, perfect for making burgers, meatballs, and more.

Commercial meat grinders, in particular, are a game-changer for butcher shops, enabling high-speed processing to meet the demands of large-scale production. Whether you’re working in a commercial kitchen or running a butcher shop, a reliable meat grinder is indispensable for producing consistently textured ground meat.

How Sausage Stuffers Enhance Butcher Offerings

Moving to sausages, an integral part of any butcher’s lineup, sausage stuffers are key. Whether you’re starting with a manual or jumping straight to an electric filler for higher volumes, these machines fill casings with ground meat and spices to create sausages.

While some models may come attached to meat grinders, standalone stuffers give you more control and efficiency, especially when producing different types of sausages in larger quantities. By facilitating the seamless production of sausages, these stuffers not only streamline the process but also enable butchers to diversify their offerings, catering to various customer tastes and preferences.

The Utility of Meat Tumblers and Mixers

Last but certainly not least, meat tumblers and mixers play a critical role in enhancing the flavor and texture of meat products. By marinating the meat under vacuum conditions, tumblers ensure an even distribution of flavors and moisture, resulting in a product that’s tender, well-seasoned, and visually appealing. It’s a process that endears products to customers for its consistency and enhanced flavor profile.

Mixers, on the other hand, are essential for homogenously blending spices, seasonings, and marinades with bulk meat, ensuring each bite is as flavorful as the last. Together, meat tumblers and mixers elevate the quality of processed meat, making them indispensable tools for any butcher aiming to stand out in the marketplace.

By incorporating these grinding and processing tools into your operations, you’ll not only boost efficiency but also expand the range of high-quality meats and meat products you can offer to your customers.

Slicing and Tenderizing Tools

In the continuum of butchery, slicing and tenderizing tools are the unsung heroes that amp up efficiency and ensure that every cut meets the mark of excellence. Expanding on the foundation laid by essential cutting and grinding tools, here, we’ll explore the key players in slicing and tenderizing that no butcher shop should be without.

Meat Slicers for Efficient Cutting

When speed and precision count, a quality meat slicer is your go-to. Picture this: a sleek, stainless steel machine that handles everything from beef to cheese with razor-sharp accuracy. The beauty of a good meat slicer lies in its ability to deliver uniform slices, whether you’re aiming for paper-thin prosciutto or perfectly even slices of roast beef for sandwiches. And it’s not just about looks; consistent slice thickness contributes to even cooking and ultimately, a better eating experience.

Investing in a high-caliber meat slicer means less time spent manually cutting and more time crafting the products your customers love. Look for slicers with adjustable thickness settings and built-in safety features to protect you and your staff during operation. Maintenance is a breeze with models designed for easy cleaning, ensuring that your machine remains in tip-top condition without a hitch.

The Benefits of Meat Tenderizers

If you’ve ever savored a bite of melt-in-your-mouth steak, you’ve experienced the magic of tenderization. Meat tenderizers are the magicians behind this transformation, turning tougher cuts into tender, flavorful delights. By physically breaking down the meat’s fibers, tenderizers enhance not just tenderness but also marination, allowing flavors to penetrate more deeply.

There are various types of tenderizers, from manual mallets to sophisticated machines that tenderize large volumes of meat efficiently. While a mallet might be suitable for occasional use, busy butcher shops will benefit from mechanical tenderizers that can handle the workload and deliver consistent results. This not only elevates the quality of the meat but also expands your product range, letting customers explore cuts they might otherwise overlook.

Incorporating these tools into your butcher shop equips you to slice and tenderize with unmatched prowess, elevating both your products and your productivity. As you navigate the world of butchery equipment, remember that each tool not only aids in creating exceptional meats but also in forging a reputation for quality and craftsmanship that customers will come to know and trust.

Packaging and Presentation Equipment

After fine-tuning the art of precision cuts and mastering the process of grinding and stuffing, your butcher shop’s next step is to focus on how your products are packaged and presented. A well-thought-out packaging and presentation strategy can significantly boost your shop’s appeal, allowing your quality meats to entice customers even before they make a purchase.

Utilizing Meat Packaging Machines

A key player in extending the shelf life of your products, meat packaging machines are essential for keeping your meats fresh and appealing. Vacuum sealers, for instance, suck out air from the packaging, inhibiting the growth of bacteria and reducing freezer burn. These machines are your go-to for ensuring that the flavors and quality of your meats remain intact from your shop to your customer’s dinner table. Moreover, they are incredibly efficient for bulk packaging, saving you time and labor. They’re not just a protective layer; they’re a statement of quality and care.

Display Cases for Attracting Customers

First impressions matter, and display cases are where your meats make their debut. Investing in high-quality, well-lit display cases can dramatically change how customers perceive your products. These cases not only serve as a refrigerated sanctuary to keep your meats at the ideal temperature but also as a stage to showcase the fruits of your labor. Organized, attractive setups invite customers to browse, increasing the likelihood of purchases. Display cases are more than just storage; they’re a silent salesman for your butcher shop, highlighting the freshness and quality of your meat cuts.

Safety Gear and Hygiene Practices

Protecting yourself and ensuring the highest standards of hygiene in a butcher shop is non-negotiable. Let’s dive into the crucial safety gear and sanitation practices that can help maintain a safe and clean working environment.

Cut Resistant and Chain Mail Gloves

When dealing with sharp tools like meat saws, butcher knives, and meat cleavers, your hands are constantly at risk. That’s where cut-resistant gloves come in. These gloves provide EN388 level 5 cut resistance, and are 100% food-safe, ambidextrous, and machine washable, making them perfect for any task involving sharp tools. Though they’ll save you from small nicks and cuts, they’re not invincible against a forceful slash from a very sharp knife. For added protection, wearing them under a vinyl glove keeps them clean and extends their durability.

If your work involves rapid movement or you’re nervous around really sharp knives, consider stepping up your safety game with a chainmail glove. Made from fine stainless steel links woven into a mesh, these gloves offer superior protection. They’re essential on a busy production line and, while they can be uncomfortable over long periods, wearing a cotton or vinyl glove underneath can boost comfort. For home butchering, they’re not strictly necessary, but they are a worthy investment for peace of mind.

Importance of Sanitation with Block Brushes

Let’s talk cleanliness. Keeping your cutting tools and surfaces immaculate isn’t just about aesthetics; it’s about safety and hygiene. Enter the block brush – your go-to tool for sanitation. Whether you’re cleaning a meat grinder, slicer, or butcher block, the right block brush can make the task more effective and efficient. By physically removing debris and residue, you ensure that your workspace remains free of contaminants.

Moreover, incorporating block brushes into your daily hygiene routine can significantly reduce the risk of cross-contamination between different meat products. Pair these brushes with a robust cleaning regimen, including regular washing, sanitizing, and air drying of all tools and surfaces. This combination ensures that your shop not only meets but exceeds health and safety standards, safeguarding both you and your customers.

Remember, safety gear and rigorous hygiene practices are paramount in the butchery business. By investing in quality gloves and prioritizing sanitation, you’re not only protecting yourself but also enhancing the overall quality of your products. Keep these practices front and center, and you’ll ensure a safe, efficient, and reputable butchery operation.

Refrigeration and Storage Solutions

After ensuring safety and hygiene in your butcher shop with the right gear and practices, the next step is to focus on how you’re going to keep your meats fresh and safe for consumption. Effective refrigeration and storage are not just crucial; they’re mandatory. Let’s dive into how you can achieve that.

Walk-in Refrigerators and Freezers

Walk-in refrigerators and freezers are the backbone of any serious butchery operation. They provide the large-scale storage solutions you absolutely need to keep large quantities of meat at optimal temperatures. Without them, managing fresh, quality meat becomes a daily gamble against spoilage. When choosing walk-in units, pay close attention to insulation and ensure they meet the specific needs of your shop. Proper insulation is key to maintaining temperature controls and energy efficiency. Moreover, considering the size and layout of your shop will guide you in selecting units that maximize storage while fitting neatly into your available space.

Keeping Meats Fresh with Proper Storage

Proper storage extends beyond just slamming the meat into the cooler. It involves strategic organization and careful temperature management to prevent cross-contamination and ensure every piece of meat stays as fresh as the day it was received or processed. Fresh meats should be stored at the bottom, preventing any potential drip and cross-contamination with other foods.

Implementing a FIFO (First In, First Out) system ensures that no meat sits out longer than necessary, reducing waste and improving inventory turnover. Monitoring the temperature diligently, ideally keeping fresh meats at temperatures just above freezing, helps in maintaining their freshness, texture, and nutritional value. This also slows the growth of harmful bacteria, keeping both your products and your customers safe.

Weighing and Measuring Devices

After exploring the realm of cutting and storage essentials in a butcher shop, it’s time to dive into another critical aspect: weighing and measuring devices. These are pivotal for ensuring the accuracy that butchery demands, from portion control to cost management.

The Necessity of Accurate Scales

Accurate scales are the cornerstone of any butcher shop. They ensure that you’re selling meat at the correct weight, which is crucial for maintaining trust with your customers and for your business’s profitability. Whether you’re weighing small cuts of meat or large batches for processing, precision is key.

Look for scales that offer high accuracy, are easy to calibrate, and can withstand the heavy usage typical in a butcher shop environment. Digital scales with clear displays make reading measurements easier and faster, enhancing efficiency during busy hours.

Measuring Portions with Precision

Precisely measuring portions goes hand in hand with the use of accurate scales. It’s not just about ensuring fair transactions but also about controlling inventory and managing costs effectively. For specialty cuts or when packaging meat for sale, having the ability to measure portions with precision ensures consistency — a trait highly valued by customers.

Tools like portioning scales or even advanced automated portioning machines can make the process more efficient and accurate. This attention to detail in portioning helps in creating a loyal customer base, as they come to expect the same high-quality experience with every visit.

Incorporating these weighing and measuring devices into your butcher shop’s toolkit is essential for running a successful, customer-focused business. They not only streamline operations but also reinforce your commitment to quality and transparency, setting the foundation for lasting customer relationships.

Frequently Asked Questions

What are the essential cutting tools in butchery?

Essential cutting tools include meat saws, butcher knives, and meat cleavers. These tools ensure precision and safety in cutting meat to desired sizes and shapes.

Why is it important to have high-quality slicing and tenderizing equipment?

High-quality slicing and tenderizing equipment are crucial for achieving uniform cuts and tenderness, which directly impacts efficiency and customer satisfaction in butchery.

What role does packaging equipment play in butchery?

Packaging equipment is vital for maintaining the quality of meat and attracting customers. It helps to ensure that meat products are presented appealingly and hygienically.

How do weighing and measuring devices contribute to a butcher shop’s success?

Weighing and measuring devices are key to ensuring accuracy in portion control, cost management, and upholding trust with customers. They help in selling meat at the correct weight and controlling inventory effectively.

What are the benefits of incorporating precise portioning tools in butchery?

Incorporating precise portioning tools helps in managing costs effectively and ensuring consistent product quality. This is essential for maintaining customer trust and streamlining operations in a butcher shop.